- en Change Region

- Global Site

- Home

- Products

- High Content Imaging

- BioPipeline PLATE

BioPipeline PLATE

High Content Imaging System

The perfect platform for flexible high content.

We chose our inverted microscope platform for high content imaging because it was the most flexible: the largest selection of objective lenses, detectors, modalities and applications available to apply to high content acquisition and analysis.

With confocal modalities, 3-dimensional high content at the highest resolution can be acquired. And with space for 44 well plates, automated runs without user attention are possible.

Key Features

Plate Robotics

BioPipeline PLATE includes a 44-plate capacity hotel with two 22 plate carriers, allowing the automated loading and unloading of plates to the imaging platform, and automated imaging to be performed.

Smart features such as plate barcode reading allow users to reference and track their data.

Automated imaging on a schedule

The NIS-Elements Scheduler allows users to maintain their individual plates and schedule open times on the imaging system to run them.

Always running, the scheduler shows an overview of all plates and their owners.

The Scheduler automatically loads plates at imaging time and executes the experiment defined by the user. When complete, the plate is returned to the incubator.

Increase analytical throughput without compromising image resolution

The combination of a high-speed resonant scanner and large field of view forms an ideal platform for high-resolution screening assays. It dramatically reduces the time needed to analyze multiple samples and conditions.

Left: A well in the 96-well plate is selected

Right: The large FOV enables acquisition of entire wells (with a 4X objective)

Large FOV enables measurement of larger areas and high-throughput analysis

Analysis Toolbox

Image analysis either during or post-acquisition is an essential tool for high content imaging. NIS-Elements includes several analysis tools as well as capabilities for user-defined custom assays that can be applied to images.

Analysis results can be used as well to direct the course of experiments in real-time.

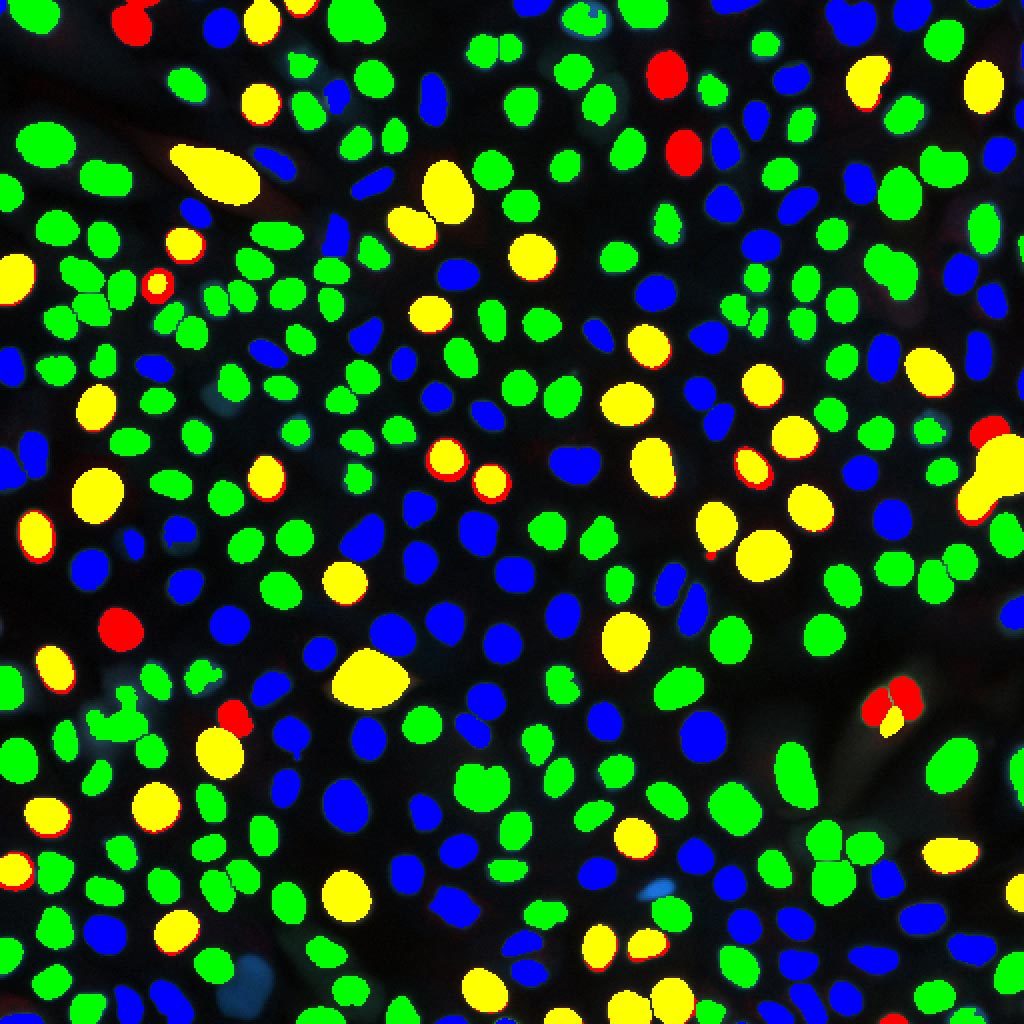

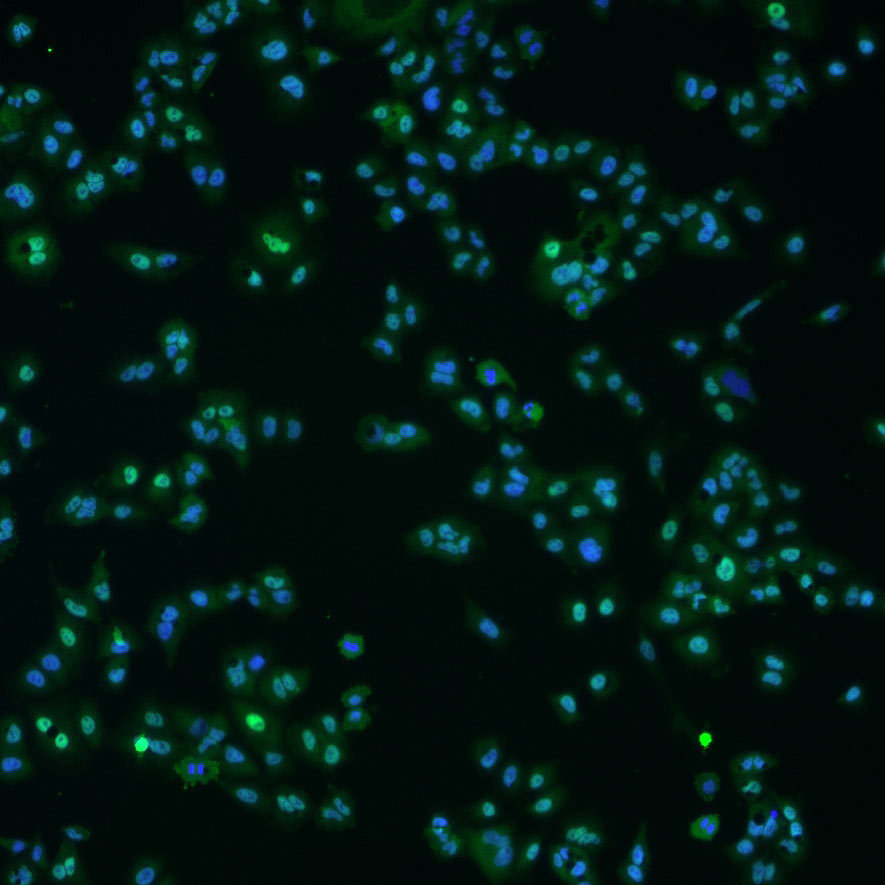

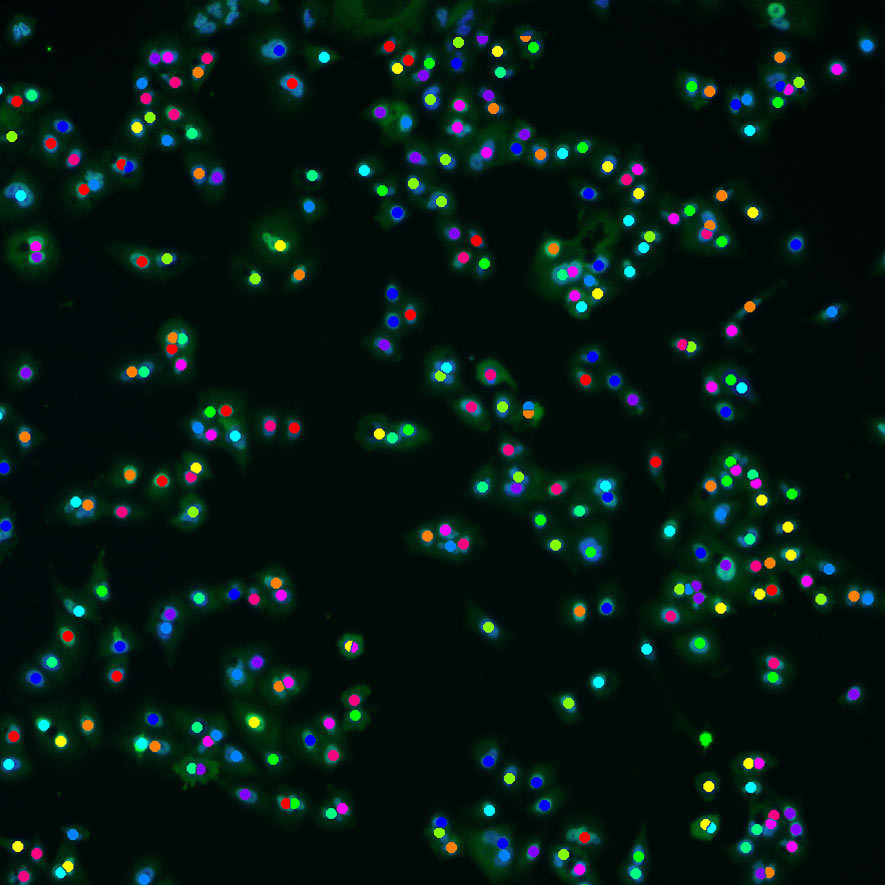

Cell labeling tool detects and counts number of cells labeled with colors, or combination of colors. It also provides the intensities iosof the multiple labelsper cell.

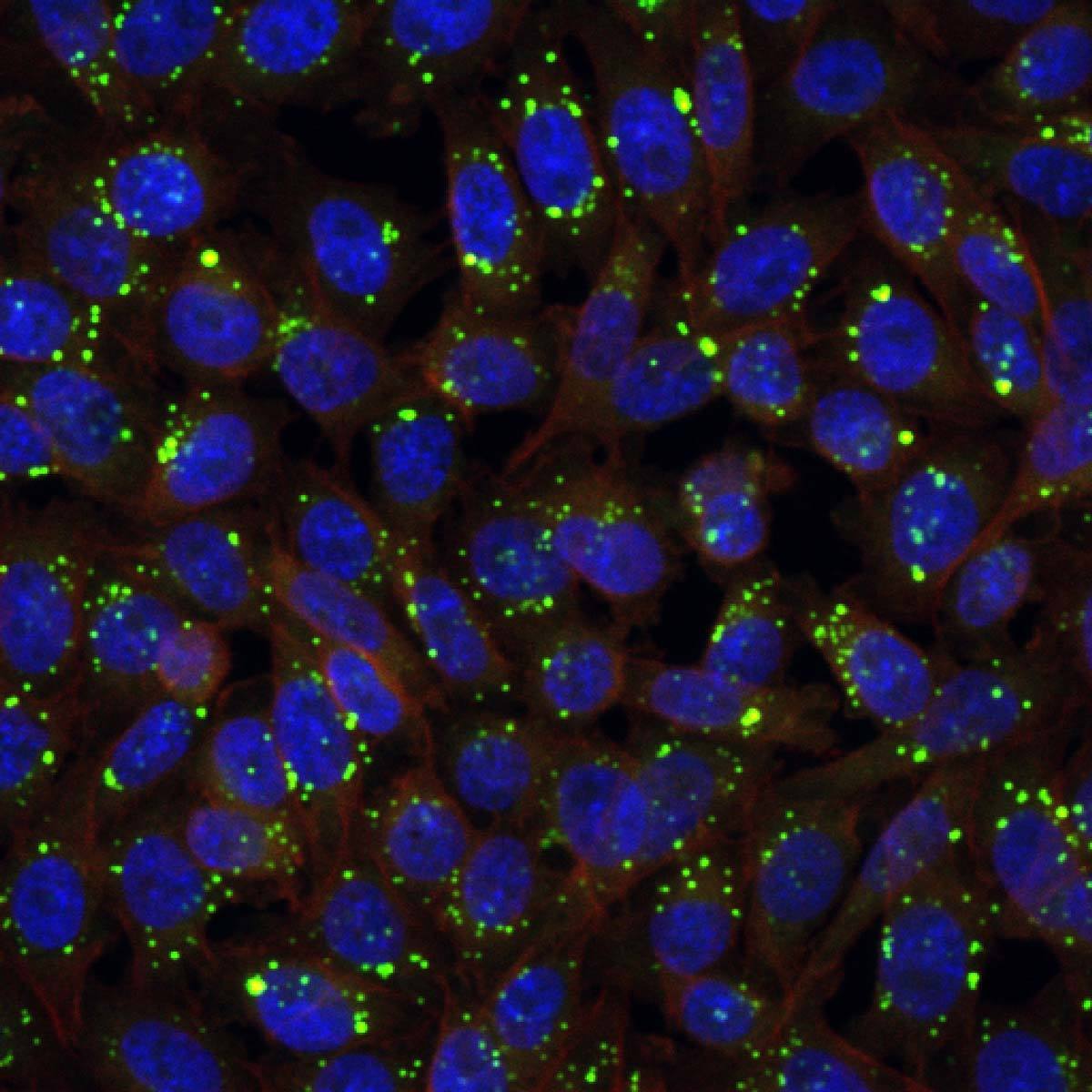

Spot counting tool detects and counts granularity in cells, creating boundaries between cells and reporting number of granules per cell.

Cell counting tool utilizes low magnification and large FOV to count objects. This provides accurate and repeatable count information that can be applied across multiple plates.

Optional Storage

High content imaging can mean large storage requirements. Having over 30x the storage capacity of a typical high-end imaging workstation, with expandability for more, the optional BioPipeline Server with direct dedicated 10GbE network connection allows for more uninterrupted imaging and offline processing and analysis.

BioPipeline’s data transfer rates from the imaging workstation to the dedicated server exceed most traditional networks by 10-100x by using dedicated 10 GbE connections.